Support

Search our resource library for the latest product documentation and related articles, videos and manuals.

We are dedicated to provide industry leading customer service and product support. See links below for support resources or contact us and let us know how we can serve you best.

Get in touch with our product support team for assistance with your Hettich product(s).

Contact Service

Find your local sales rep. and reach out to them directly with any sales-related inquiries.

Find Your Local Rep

Search our extensive Resource Library for articles, documents, videos and more.

Resource Library

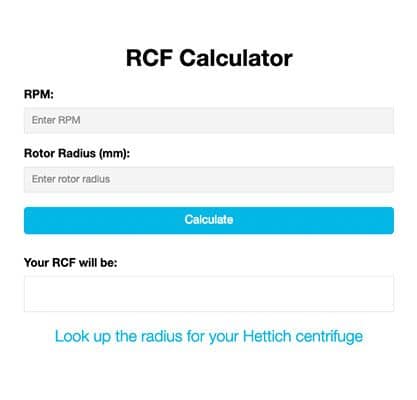

Our RCF or RPM calculator will help you determine the RCF or RPM value for your centrifugation cycle.

Determine RCF/RPM

Keep your lab running and optimize the performance of your instrument with Hettich Service Agreements. We offer various preventative maintenance plans and services to protect your investment and help avoid unnecessary downtime.

Service Agreement RequestSee our support FAQ for answers to common product questions.

Regular cleaning and maintenance are essential in prolonging the life and safety of your Hettich equipment. Please refer to the unit’s operator manual and follow the instructions. These actions will not only extend the life and security of your product, but they will also reduce unnecessary repair costs for long-term, read more...

Video demo of how to install a centrifuge rotor on most Hettich models. read more...

Video demo of how to remove centrifuge transports bolts on most models. read more...

MSDS for Hettich Grease Part. No. 4051. read more...

100 Cummings Center, Ste 136L

Beverly, Massachusetts 01915

United States

Hours of Operation:

Monday – Friday 8:30 AM – 5:00 PM

Eastern Standard Time

Closed most Holidays

Toll Free: 1 (866) 370-4388

Phone: (978) 232-3957