Water Retention Value in Pulp and Paper Application Note

This application note provides information on specific application methods and the use of Hettich products. (more…) read more...

File size: 519.7 kb

The water retention value (WRV) is an essential parameter in pulp and paper manufacturing. It indicates the ability of a sample of wood fiber or pulp mass to retain water.

The WRV changes during the manufacturing process. For instance, it rises continuously during the grinding process due to the increasing separation into fibers. The WRV consequently provides valuable information on the impact of the individual steps in the pulping process on the fibers produced and to what degree the pulp mass is suitable for paper manufacture.

The method used to determine the WRV has been standardized and is described in the international standard ISO 23714:2007. Whereas in the past, the sample holders were specially manufactured and therefore expensive or had to be fabricated for their intended use, Hettich now offers a test-padholding unit of type A.1 as given in ISO 23714:2007 as standard centrifuge accessories.

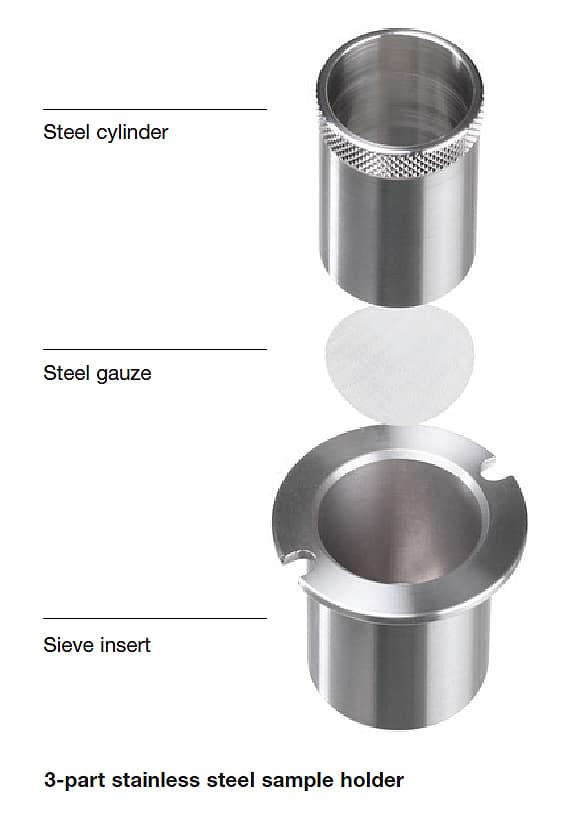

The test-pad-holding unit

The test-pad-holding unit has three parts, all of stainless steel:

Method

ISO 23714:2007 “Pulps – Determination of water retention value (WRV).”

Hettich products are designed to help you achieve optimal results for your application and are built to perform to the specifications outlined in the operators manual. For application-specific information and settings, please refer to your organization’s standard operating procedure. As always, our Hettich representatives are here to help determine which Hettich products and accessories best fit your laboratory requirements.

This application note provides information on specific application methods and the use of Hettich products. (more…) read more...

This product sheets provides a comprehensive overview of the unique product features specific to the model. (more…) read more...

Hettich manufactures centrifuges for any standard laboratory application.